engraving wood and other materials

For hotels, restaurants, bars and more

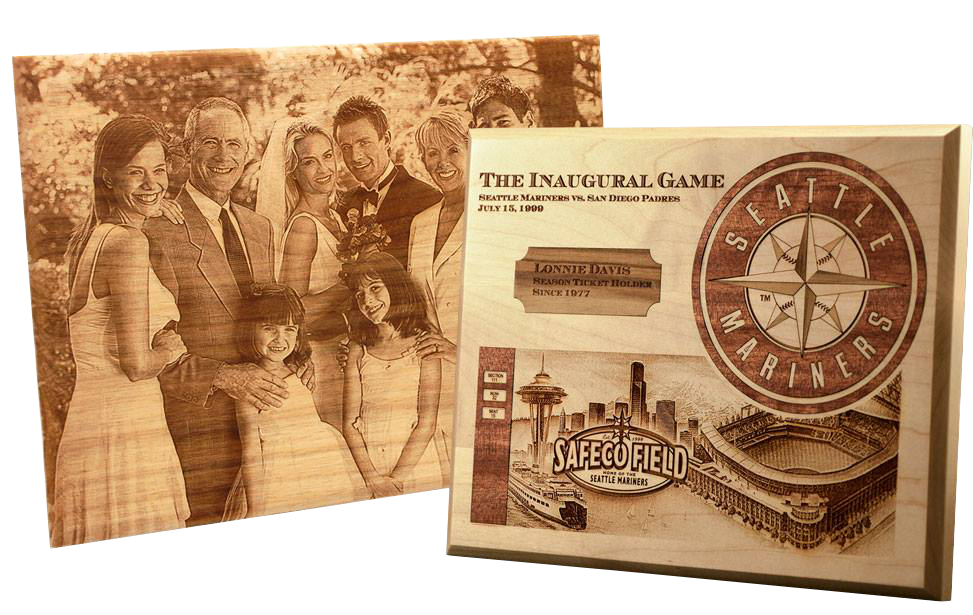

We offer laser engraving wood - accurately and elegantly.

It's hard to think of another, as precise engraving as laser engraving. In the case of the services we offer, the accuracy reaches one thousandth of a millimeter. What the human eye will not see will do the laser. We use this advanced technology to prepare diversified products. Personalized advertising items used on a daily basis in gastronomic premises, engraving can be placed on almost every assortment in our store, it is possible to order even such wooden items that are not currently available in our store.

We will do everything to get them and fulfill your expectations.

Our products are elegant, made with excellent precision and durable. Please contact us, everything is a matter of agreement.

We have professional and precise laser plotters with a maximum working area of 60 x 90 cm + a through table. In addition to the engraver on the assortment from our store, we can perform engraving services such as:

- engraving wood

- plywood engraving

- engraving painted metal

- engraving glass and crystal

- Plexiglass engraving

- engraving cork

- leather engraving

- we also engrave selected types of paper, textiles and ceramics.

We offer:

- cutting in wood

- cutting in plywood

- cutting in plexiglass

- cutting in a traffic jam

- cutting in the skin

- cutting in the selected type of paper and textiles

VALUATION

Due to the variety of materials used by us and the techniques we perform, we are not able to place a binding price list on the website.

The price depends on many factors: the type of material, the complexity of the order, the amount of time needed, the number of copies (surface of the item) and the technology used.

Feel free to contact us!

Laser engraving wood – the most durable method of marking products!

Laser engraving method of the 21st century.

Laser engraving nowadays it is one of the most popular and also the most durable method of marking on objects. With currently developed technologies and the accelerating development of electronics and technology, the use of CNC machines is not new. Each plant dealing with this type of services should have at least one machine of this type in its machine park. These machines are professionally called plotters.

There are many types of plotters, including laser plotters. However, we can also distinguish milling plotters, turning plotters, cutting plotters, plasma or machining centers. All these machines are technologically advanced and accurate like robots, numerically controlled machines directly from a computer. These are tools that you only need to know about your computer, hardware and their operation. They do not need any input from manual or technical skills of the operator.

Usually, after proper preparation of the computer file, in the appropriate format / extension, it is enough to upload the file into the device’s memory. Select the device’s parameters accordingly, and the rest will be done for us by this kind of electric robot. A plotter with a computer is an inseparable set, without which you can not start work. The plotter’s work cannot be initiated manually, everything is fully automated and carried out remotely. When the plotter already knows what to do, just by applying a computer file to its memory, no further input is needed.

Appropriate selection of parameters during laser engraving wood.

Speaking of parameters, on the example of a laser plotter, we can distinguish the following values: laser power, which is most often determined as a percentage (%). Where 100% is the maximum tube power and 0% is the lack of power. Laser power is actually the power of a laser tube. Tuba is a component of the entire device, responsible for energy production. This energy is used to perform work related to marking, i.e. laser engraving wood, of the object, or cutting it. There are several types of laser tubes and their power.

Among others, glass, liquid-cooled and metal tubes. Synrad. A liquid-cooled glass laser tube that needs its circulation and systematic cooling of the liquid must have a liquid cooler in the kit. This cooler is designed to cool this liquid and prevent the tube from overheating. To be able to enjoy the maximum performance of the laser tube for a long time, you must follow a few rules and take care of it. A laser tube is not a component that works well indefinitely, especially when it is not properly maintained. To these principles of proper care, one of the most important components of the machine, is work in appropriate atmospheric conditions.

A few simple rules to follow!

These appropriate conditions include, but are not limited to, temperature. The ambient temperature during operation should not exceed the temperature range between 5’C and 40’C. Temperature outside this range is very unsuitable and harmful to the device. For some laser plotters this range may be even narrower. The humidity in the laser room is also an important issue. It can not be too large, because this issue also has a significant impact on the life of the laser plotter tube. In addition to atmospheric issues, there are a few other rules that only people who operate the equipment have influence on. One of them is the need to let the laser tube reach the right temperature right after starting the device. Just after starting it, you should “give time” to the laser tube and after turning on the device wait a few minutes with work.

These are important rules for the plotter

Another issue that can significantly extend the life of the laser tube is to avoid the device working at maximum tube power. Work at 100% laser power compared to 80% is much more unfavorable, despite the fact that the work can be done in a shorter time! It is always worth, however, to save quite large costs associated with the replacement of this costly part. Reduce the power a bit and extend the working time. It is assumed that it is most advantageous to work at a maximum laser power of 80%. By following these few simple rules, certainly every laser plotter operator will significantly contribute to extending the life of the laser tube at the maximum power range. Because each wearing tube gradually loses its power, which is the first and last sign of tube wear.

As we have already established, it is one of the most expensive and fastest wearing parts of the whole plotter. Only by observing the rules of use can contribute to the extension of the machine’s functionality and will help save large replacement costs. Only good, and with maximum power, the working machine, which is a laser plotter, is the best device for the production of wooden advertising gadgets. Wooden advertising gadgets are inseparably connected with the laser engraving wood method, which can be made only on strong equipment, which will always be a well-groomed laser plotter.

Laser engraving wood – Is wood a good material?

Laser engraving wood is a process of interference in the material, consisting in making recesses on the surface of the material, resulting in sculpting. These depressions, reflecting the graphics previously introduced into the machine’s memory, have an additional color. The color of the carvings, depending on the blow settings on the material, takes on a darker or lighter shade of brown. This shade and the structure of the engraver will depend not only on the blowing power, but also on the hardness and structure of the material.

For example, based on wood, the structure of the engraving wood on a species of wood such as soft pine and hard beech, the quality of the same engraving will be slightly different. The reason for this will be the difference in the hardness of the material itself as well as the arrangement of the rings. Of these two types of wood, beech is more grateful for laser engraving wood.

Beech is hard wood, and its rings and outgrowths are of this structure and hardness. In addition, the wood itself is light wood and rarely has discoloration. For these reasons, we drewpart.pl decided to make wooden advertising gadgets from this material.

Our wooden advertising gadgets

All our wooden advertising gadgets, such as for example: wooden cutting boards with engraving, wooden boxes with engraving, wooden blades with engraving, wooden dishes with engraving such as wooden bowls with engraving or wooden plates with engraving, wooden spoons with engraving, wooden grandparents for nuts with engraving, boxes for decorations of plywood with engraving, wooden kitchen utensils with engraving, cupboard with engraving.

Wooden phone stands with engraving, wooden boxes for wine with engraving, wooden wedding decorations with engraving, advertising key rings, wooden graters with engraving, decorations made of plywood with engraving, wooden beer mugs with engraving, wooden toys with engraving, wooden carpets with engraving, these and many other wooden advertising gadgets with the company logo or other graphics in the form of engraving, were made of a material that is wood beech.

Laser engraving – what does the process look like?

But what exactly is laser engraving? As we mentioned earlier, it is a kind of carving process on material. But how is this done? And what happens to the material that recesses resemble graphics? All this happens thanks to the laser, and more precisely its light, which works similarly to fire. This light is produced in a laser tube, to which we have already devoted a few words. The power of the light will depend on the power and quality of the laser tube. The tube is usually located at the back of the CNC laser plotter.

The light produced in it is directed towards the material by means of mirrors set in the right angle and position. Mirrors in the whole system, which can be called a light transport system, usually there are 3 pieces. Two of the three mirrors control the horizontal path of the light, changing only its direction, most often by an angle of 90 ‘. They should therefore be angled 45 ‘to the direction of the light. The third mirror is responsible for changing the vertical direction of the light and reflects it at an angle of 90 ‘down towards the material. The light, however, encounters the lens before coming into contact with the material.

Laser engraving and cutting plywood

The lens’s task is to focus the light, which gives me more power and reduces its diameter. This is what makes the laser plotter powerful and is an extremely accurate tool at work. After explaining this process, we can add that not only the laser tube affects its power and accuracy, but also has the participation and weight of the laser plotter’s optician. Good quality, neat and regularly cleaned optics are the key to the success of a well-functioning laser engraving that accurately reflects the graphics.

The last very important aspect during the work of a plotter performing cutting or laser engraving is air blowing. During the laser cutting process, the blow first prevents the ignition of the material that is already affected by the light focused by the lens. Supports the process of cutting / burning the material, and prevents it from getting smoked. The blow, which works with great power, purges the smoke generated during the work directly into the flue system. During the laser engraving process, the blow also plays a very important role, it prevents the plotter’s lens from getting dirty.

Laser engraving and the production of wooden advertising gadgets.

All these components of the laser plotter make up the appropriate performance of the laser engraving process. After which the best-quality wooden advertising gadgets, as well as decorations from plywood or other materials can be created. Laser engraving is one of the most durable methods of marking products with the company’s logo or other preferred graphics. The durability of this method is influenced by the fact that the cavities in the material are hard to wipe and redraw. This method is much better against the background of surface prints on the material, which easily wear off and remain hardly visible. In addition, the smoking effect is very durable and does not lose color over time. Laser engraving is certainly one of the most durable methods of marking products.

If you have questions or interest in the quote, please contact us

Address for quotes: biuro@drewpart.pl

Our advantages

High quality

Precision and many years of experience of local producers

Modern products

Designed for the pursuit of the latest trends and design

Fast shipping

Implemented by the best couriers, combined with modern logistics centers

Fast and completely free support

Taking care of our clients, we help and answer every message as quickly as possible.

Polecam chlebak drewniany , chleb o wiele wolniej w nim wysycha niż w tym plastikowym .Wygląda o wiele lepiej plus jest trwalszy. No i świetnie wygląda w kuchni.Solidnie wykonany!!!

Piotr

Bardzo gorąco polecam Drewpart.pl. Zakupy w tym sklepie to czysta przyjemność. Sama zakupiłam Tacę śniadaniową. Obsługa bardzo miła, przesyłka dotarła w ekspresowym tempie, a co najważniejsze produkt zgodne z opisem, w dodatku solidnie i fachowo wykonany. Ślicznie wygląda w mojej nowej kuchni!